Cnc Glass Working Center

Cnc Glass Working Center

Introduction of machine

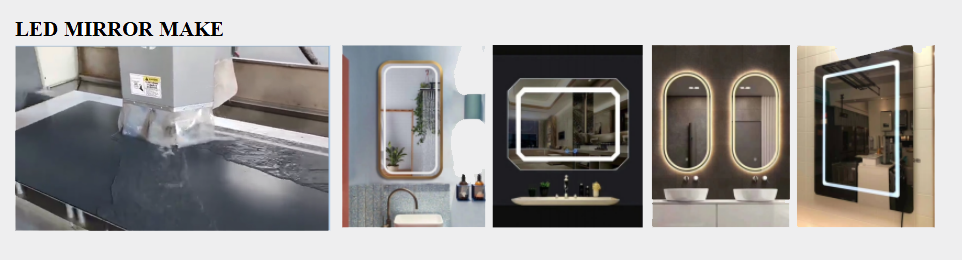

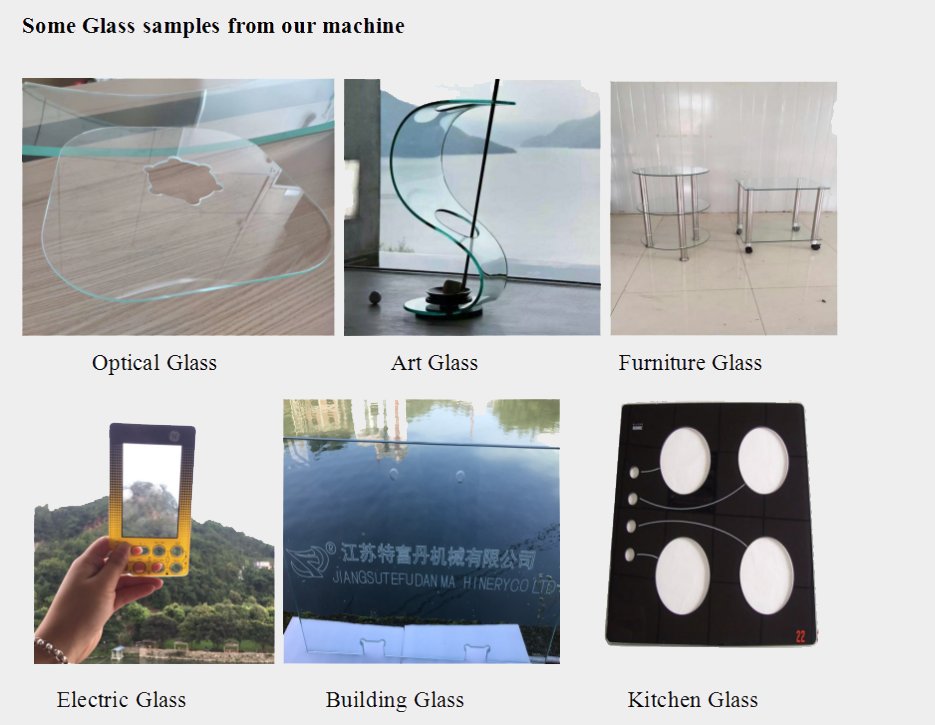

CNC Glass Working Center is a new generation machine which is professional for glass deep processing.We adopt the TAIWAN SYNTEC CNC system combined with BAINENG software.It is fully auto-complete from pattern design to product processing. It can be used for Frosting,Edging,Milling,Drilling,Shaping,.Beveling,writing and polishing on glass.So it’s a good choice for mass production for Led Mirror,building glass,furniture glass,decoration glass and bathroom glass.

Operating Principle

Firstly, design the patterns with CAD software, then transfer the CAD drawing to Baineng System and set parameters. The Baineng System can calculate the best route and generate code. Thirdly copy the codes to the computer. The computer will read the codes and transfer to the machine, so the machine can start to work automatically.

Function

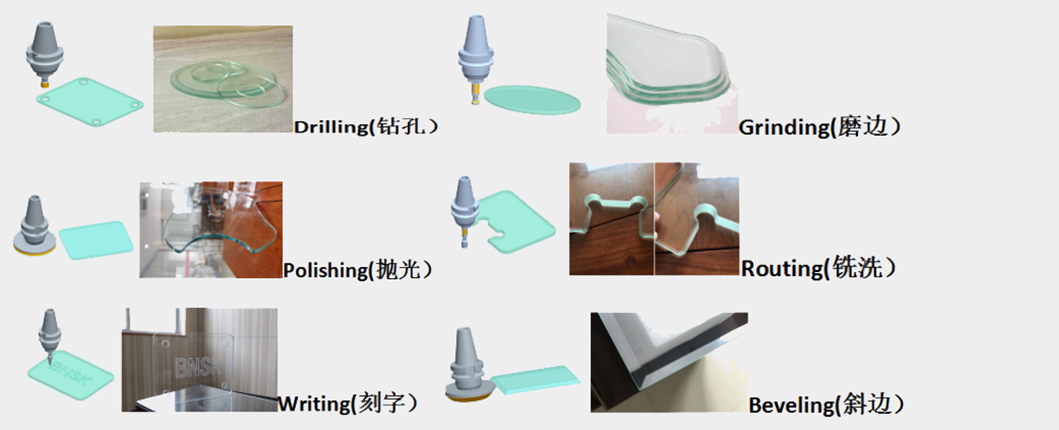

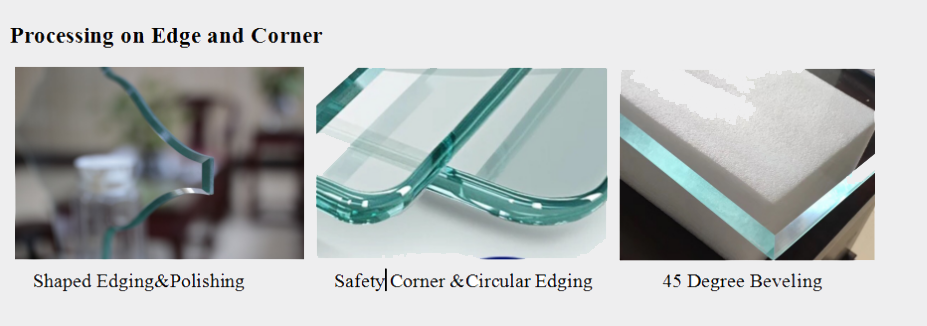

The machine can be used for cutting,drilling,milling,shaped notching,edge grinding ,beveling ,writing and polishing on glass

Advantages

Except BN-T2412,other three models BN-T2620/BN-T3016/BN-T3020 can process at least two glass sheets at one time(like below the picture),when the machine finish A glass sheet and then processing B glass sheet,in the meantime you can unload the finished one and load new glass sheet.So that the machine is not stop working and save much time.The efficiency can be increased by 25%-30%.Many other machines can only process one glass sheet at one time.When it finish this glass sheet,the machine must stop and wait for people changing new glass sheet.

Software advantage

- Firstly,make the drawing with CAD, then transfer the CAD drawing to Baineng software and set parameters. The Baineng software can calculate the best route and generate code. Thirdly copy the codes to the Syntec controly system. The Syntec system will read the codes and transfer to the machine, so the machine can start to work automatically,including automatically tools change.

- Our machine has high processing speed and great precision.Take the grinding and polishing of shower door for example,the production capacity is 4.5-5.5meter per minuter.

- The hiding tool library:unlike other manufacturer make the tools explosive to the air,we develop the hiding tool library to protect the tools from rusting.And it’s fully automatical tools change.

Configuration Details

- CNC system and Wireless handle remote from TAIWAN SYNTEC

- Actuator,Transducer and Servo motor from TAIWAN SYNTEC 。

- Electrical equipment from GERMANY Schneider

- Ball screw and Linear from TPI OR HIWIN

- Electric spindle: We adopt the electric spindle discharge central water(pls see below the picture).

- We adopt the electric spindle discharge central water(pls see below the picture).The central water not only provide cooling function so it can drilling,milling and notching,but also increase the service life of tools.

Technical Parameter

| MODEL NO. | BN-T2412 | BN-T2416 | BN-T2620 | BN-T3016 | BN-T3020 | BN-T3720 |

| Stroke of X.Y.Z-Axis | 2400*1200*200mm | 2500*1700*200mm | 2600*2000*200mm | 3000*1600*200mm | 3000*2000*200mm | 3700*2000*200mm |

| Speed of X.Y-Axis | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) |

| Speed of Z-Axis | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) |

| Max Size of Glass | 2400*1200(mm) | 2400*1600mm | 2600*2000(mm) | 3000*1600(mm) | 3000*2000(mm) | 3700*2000(mm) |

| Min Size of Glass | 200*200 (mm) | 200*100 (mm) | 200*200 (mm) | 200*200 (mm) | 200*200 (mm) | 200*200(mm) |

| Glass Thickness | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40(mm) |

| Tool Library(PCS) | 1*4 | 2*4 | 2*5 | 2*4 | 2*5 | 2*5 |

| Spindle Speed | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) |

| Spindle Power | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) |

| Total Power of Machine | 17-21kw | 17-21kw | 17-21kw | 17-21kw | 17-21kw | 17-21kw |

| Voltage | 380V | 380V | 380V | 380V | 380V | 380V |

| Internal Water Consumption | 3 L/min | 3 L/min | 3 L/min | 3 L/min | 3 L/min | 3 L/min |

| External Water Consumption | 100 L/min | 100 L/min | 100 L/min | 100 L/min | 100 L/min | 100 L/min |

| 空气压缩Air Compression | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA |

| Weight | 4800kg | 5000kg | 6000kg | 6000kg | 6500kg | 8100kg |

| Shipment Size | 5000*2300*2300(mm) | 4700*2300*2300mm | 5200*2300*2300(mm) | 5600*2300*2300(mm) | 5600*2300*2300(mm) | 6300*2300*2300(mm) |

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.