CNC Vertical Glass Drilling and Milling Machine

CNC Vertical Glass Drilling and Milling Machine

Baineng Vertical Glass drilling and milling machine with high technology. It can perfectly perform complicated working in short time, and the processed sheet is of high level which realized to obtain a CNC machine with smallest investment.

The Vertical CNC working center applies numerical operation and control system to achieve dynamic management of each axis and speed precision control. So the shape is of precision and the processed sheet is of high quality. It is a CNC vertical drilling and milling machine to process simple and complex drawing and featured by the most advanced technology. It is a solution to the requirement on processing precision, high speed and ease operation.

The machine can automatically process complex drilling and milling functions on large flat glass. When the glass was loaded on the feeding rack, the machine begins to execute the prepared program on drilling, milling, etc.

The flexibility of the control system can meet the requirement of different products, the whole work is finished automatically. This machine is suitable to process structural glass (Frameless door, glass curtain wall etc.) The function including: Drilling, Milling

The vertical glass-working machine; with all the main part protectively covered. The structure is convenient to load and unload the machine and occupied less area. It also can reduce the obstruct and easy to process the glass sheet, or even advantaged to the coolant water system.

BAINENG Software is developed by our IT team.It has common patterns in the system.So you only need to input the parameter then the best route is generated automatically. Baineng software is easy to learn and operate.You just need to transfer CAD2000.dxf to Baineng software ,then it can automatically generate the codes.

Operation process:

- File import→select the lines→set the parameters→update the parameters→generate the codes

- Install Baineng CAM software on Windows system,the user can draw various shapes on CAD,then generate the code by CAM to start processing automatically.

- Developed Proprietary MARCO software for the commonly used doors,like Shower Door,Overhang-Door,Floor Hinge etc.,it can be filled correct size while processing,not need make CAD drawing.

- Developed Scanning code recognition function for small batch orders.

Applications

The machine can be applied for mass production for frameless shower doors,Sliding door,glass curtain wall.etc.So that it can save a lot of labors and costing.

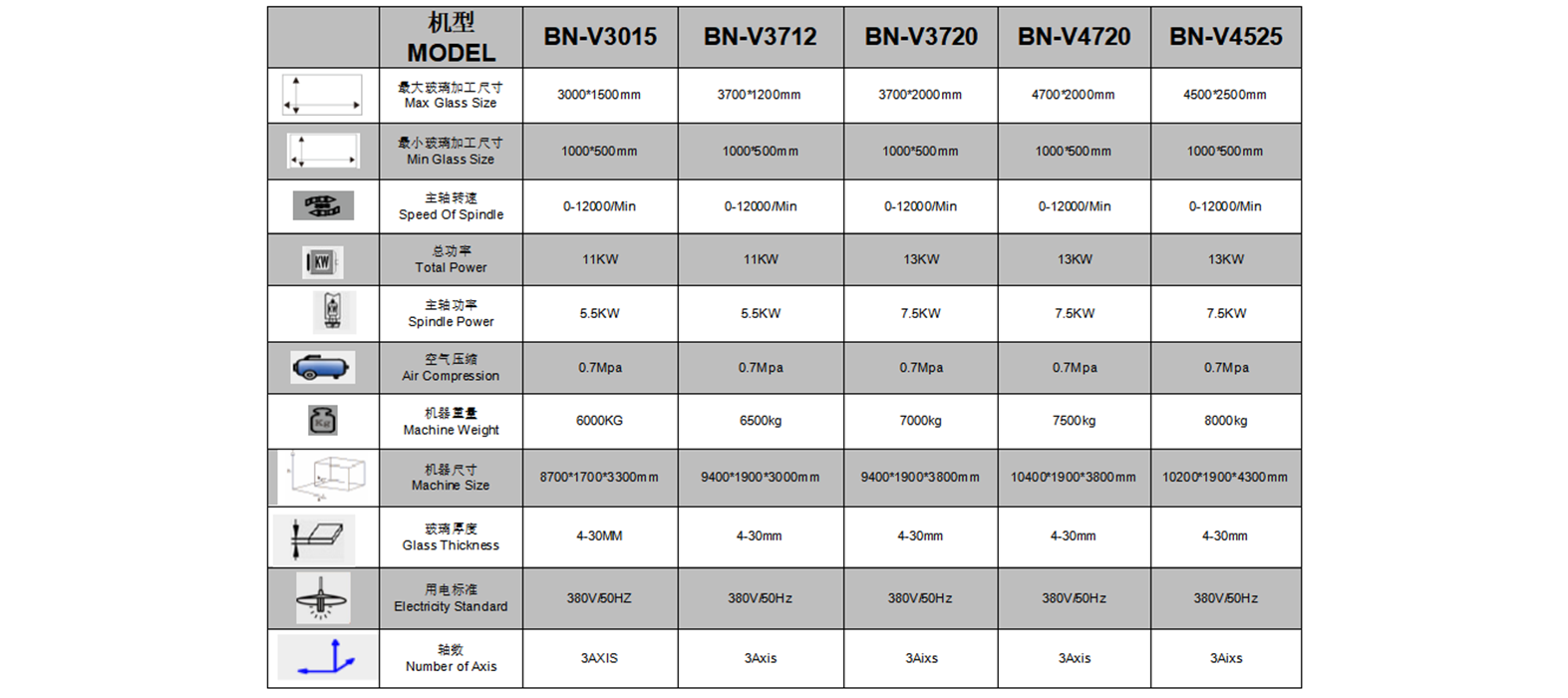

Technical Parameter

Components for machine

| Description | Brand | Made in |

| Linear Guide | Hiwin | Taiwan |

| Ball Screw | HIWIN/TPI | Taiwan |

| Servo Motor | Mitsubishi/Syntec | Japan/Taiwan |

| Bearing | NSK | Japan |

| Sliding Block | Hiwin | Taiwan |

| Control System | Syntec | Taiwan |

| Control Electrical | SCHNEIDER | France |

| Image Converter Software | BAINENG | China |

| Spindle | Baineng | China |

| Synchronous Belt | / | China |

| Air Cylinder | Airtac | Taiwan |

| Synchronous Wheel | / | China |

| Water Pump | / | China |

| Steel Plate | Baosteel | China |

| Protection Cover | / | China |

Parts with machine

| Description | Quantity | Remark |

| Gloves | 1pair | / |

| Adjustable cushion | 4pcs | / |

| X axis synchronous belt | 1pcs | / |

| Toolbox | 1box | / |

| Adjustable wrench | 1pcs | 250*30(mm) |

| Allen wrench | 9pcs | S1.5 S2.0 S3.0 S4.0 S5.0 S6.0 S8.0 S10.0 S.12 |

| Inner Allen screw | Some pcs | M6*10,M6*20 |

| Allen Nut | Some pcs | M10*20,M6*10,M6… |

| Thread seal tape | 1pcs | / |

| Water Pump | 1set | / |

| Transformer | 1set | / |

| Spindle water cooled machine | 1set | / |

| 3functions in one tool | 3pcs | Including milling,drilling,chamfering |

Our Advantages

Quality

CE Certificate & 1 Years Warranty, the film has high purity, good compactness and uniformity

Service

After-sales team of 35 people, overseas after-sales service is available.

R & D

50 R&D personnel with more than 10 years experience. More than 60+ patents.

Customizable

Multiple coating technologies in a single system.